SUAC is amongst one of the best manufacturers and providers of fire fighting equipment, fire protection systems, and safely engineering solutions.

Dedicated to the science of firefighting.

Fire Fighting Pumps:

SUAC’s new range of CE Marked and NFPA Compliant fire Pumps provide you a reliable solution for your fire fighting needs by combining the stringent quality measures with our proven experience in the fire protection field. We can offer you a complete package of service starting from engineering assistance to field start-up and periodic maintenance. Each Pump sets are tested in our factory prior to dispatch, as per NFPA standards. These pumps are covered by a warranty of one year subject to standard terms and conditions.CENTRIFUGAL FIRE FIGNTING PUMPS:

1: Complete unit responsibility.2: Complete in house fabrication capabilities.

3: Hydrostatic testing facilities

4: Operation run test as per NFPA Requirements.

5: Horizontal split case pumps for capacities of 750 Us GPM,1000 Us GPM,1250 US GPM and 1500 US GPM.

6: Drivers: Electric Motor drive or diesel engine drive.

7: Electrical testing capabilities for motors and controllers as per NFPA standards.

8: Capable to supply additional accessories wherever required.

PUMP CASING:

This casing is axially split, which permits removal of the complete rotor without moving either piping or motor. Pumps generating high heads have double volutes to reduce radial forces, ensuring minimal shaft deflection and low bearing loads. replaceable wear rings protect the casing the impeller running clearances.IMPELLER:

The closed impellers have double curved vanes. The double suction design gives practically zero axial forces. Each impeller is dynamically balance according to ISO 1940-1 standard.Bearings:

On both sides grease lubricated deep grove ball bearings, sealed for life.Shaft seal:

Soft-packed shuffling box, Cooling lines are provided for additional cooling of the graphite impregnated type gland packing.End suction fire pumps:

1: Complete unit responsibility.2: Complete in house fabrication capabilities.

3: Hydrostatic strength testing facilities.

4: Operation run test as per NFPA requirements.

5: End suction models for capacities from 50 to 500 US

GPM.

6: Driver electric motor drive or diesel engine drive.

7: Electrical testing capabilities for motors and controllers as per NFPA standards.

8: Capable to supply additional accessories wherever required.

9: Capable to supply single skid mounted fire pump set.

Pump Casing:

The casing is designed for back pull-out which permits the removal of complete rotor unit without removing suction and discharge pipe. The cast iron volute top centerline discharge with axial suction incorporating cast inlet vane to give best flow to impeller eye.Impeller:

Impeller is double shrouded type. It is hydraulically balanced and positively driven by shaft key and axially locked between sleeve and impeller nut.

Bearings:

Driven end/non driven end bearings are grease lubricated deep groove ball bearings, sealed for life.

Shaft seal:

Soft - packed stuffing box. Graphite impregnated type gland packing.

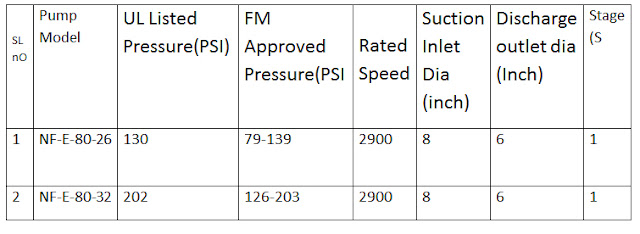

RATED CAPACITY 250 US GPM

Rated Capacity 500 US GPM

1000 GPM Capacity

Approvals

SUAC has successfully achieved ISO 9001 quality management system certified by European Union Safety Standards. Further we have achieved product certification from Engineering Development Board – Pakistan for our Fire Extinguishers, fire hose reels, Centrifugal fire pumps, diesel engines for driving Fire pumps, Fire fighting equipment & certification for fire alarm system installations.Engineering Capabilities

SUAC is backed by a team of professionals who are well qualified and specialized in their respective field viz - Design, Development, Production and Project Implementation. Our investment in applied research and development program concentrates on innovations which meet customer needs.Quality Systems

SUAC is certified to ISO 9001 Quality system by American Global Standards. Our manufacturing processes are based on a quality system that ensures the use of raw material confirming to relevant International Standards. Our in process production is monitored by work standards & quality plans confirming to relevant International standards enabling us to deliver quality products.Our aim is to become your supplier of choice while focusing on value added products and services that matter most to you.